Unlocking the Potential of Augmented Reality for Machinery Maintenance

As technology continues to advance at an unprecedented pace, industries across the board are embracing innovative solutions to enhance their operations. One such technology that has gained significant traction in recent years is augmented reality (AR). With its ability to overlay digital information onto the real world, AR is revolutionizing various sectors, including machinery maintenance. In this article, we will explore the key benefits of using AR for machinery maintenance and provide strategies for implementing this transformative technology.

Enhanced Efficiency and Productivity

One of the primary advantages of utilizing AR in machinery maintenance is the significant improvement in efficiency and productivity. Traditional maintenance processes often involve referring to bulky manuals or relying on experienced technicians to diagnose and fix issues. However, with AR, technicians can access real-time information and step-by-step instructions directly through wearable devices, such as smart glasses or helmets.

AR overlays relevant data, such as schematics, diagrams, and maintenance procedures, onto the technician’s field of view, eliminating the need to juggle between physical documents and tools. This streamlined approach reduces the time required to diagnose problems, locate components, and perform repairs, ultimately minimizing equipment downtime and maximizing productivity.

Remote Assistance and Collaboration

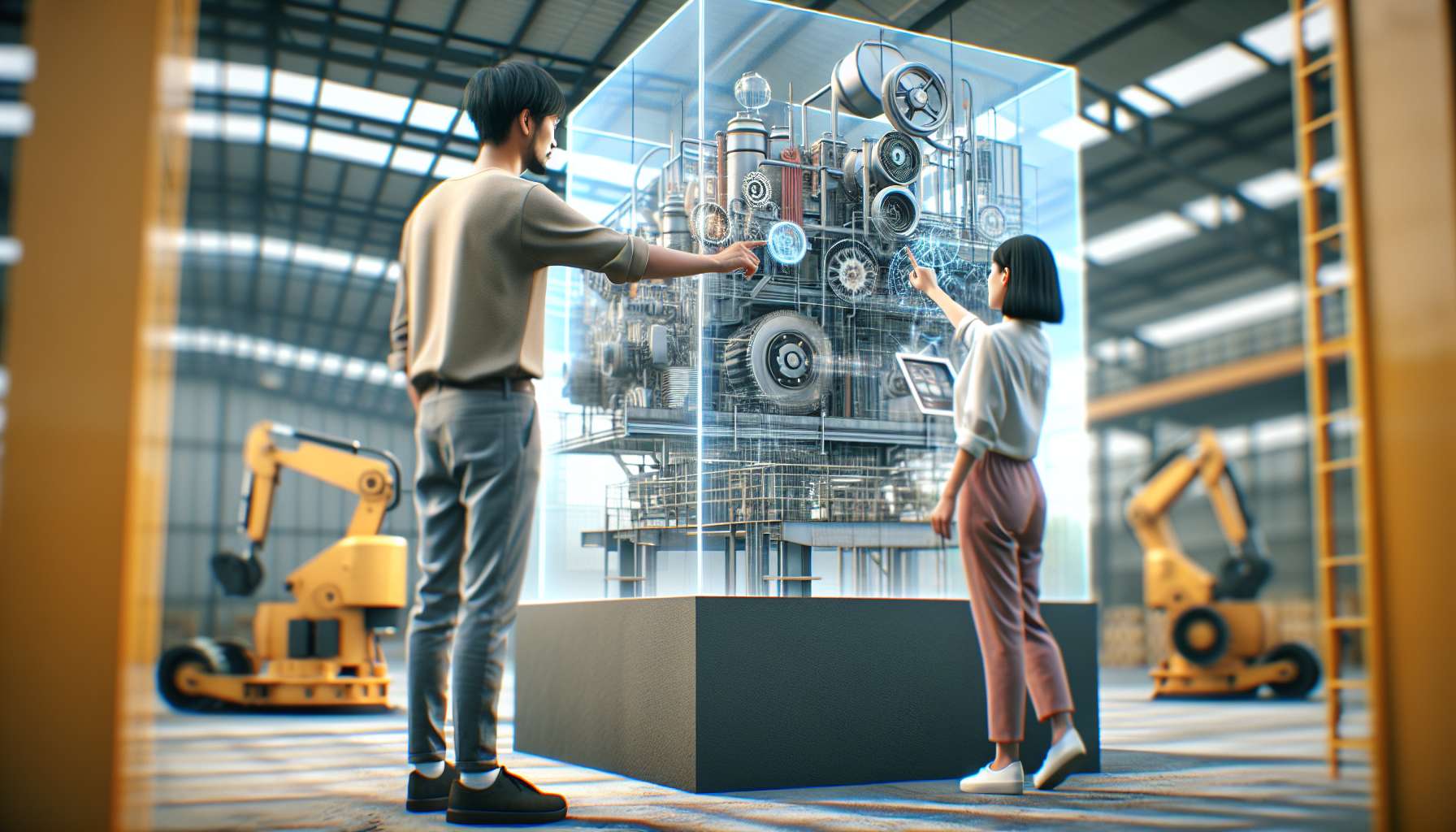

Another significant benefit of AR in machinery maintenance is its ability to facilitate remote assistance and collaboration. In complex maintenance scenarios, technicians often encounter challenges that require expert guidance. With AR, remote experts can virtually join the technician’s field of view, providing real-time guidance and support.

Through live video feeds and AR annotations, remote experts can visually identify issues, mark components, and guide technicians through complex repair procedures. This remote collaboration not only saves time and travel costs but also enables organizations to leverage the expertise of their top technicians across multiple locations, ensuring consistent and high-quality maintenance practices.

Training and Knowledge Transfer

AR also plays a crucial role in training new technicians and facilitating knowledge transfer within organizations. By overlaying digital instructions and interactive simulations onto real-world machinery, AR enables trainees to learn and practice maintenance procedures in a safe and controlled environment.

AR-based training programs provide a hands-on experience, allowing trainees to familiarize themselves with equipment, identify components, and perform maintenance tasks without the risk of damaging expensive machinery. This immersive learning approach accelerates the training process, reduces errors, and ensures that technicians are well-prepared to handle real-world maintenance challenges.

Implementing AR for Machinery Maintenance

Integrating AR into machinery maintenance processes requires careful planning and execution. Here are some strategies to consider:

- Identify Suitable Use Cases: Assess your maintenance workflows and identify areas where AR can add the most value, such as complex repairs, equipment inspections, or troubleshooting.

- Choose the Right AR Hardware: Select AR devices that align with your specific maintenance requirements, considering factors like comfort, durability, and compatibility with existing systems.

- Develop Customized AR Applications: Collaborate with AR solution providers to develop tailored applications that integrate seamlessly with your maintenance processes and provide the necessary functionalities.

- Train and Support Technicians: Provide comprehensive training to technicians on how to effectively use AR devices and applications. Establish a support system to address any technical issues or challenges that may arise.

- Continuously Evaluate and Improve: Regularly assess the impact of AR on your maintenance operations and gather feedback from technicians. Use this information to refine your strategies and optimize the use of AR technology.

As the adoption of AR in machinery maintenance continues to grow, organizations that embrace this technology gain a competitive edge by improving efficiency, reducing costs, and enhancing overall equipment performance. By leveraging the benefits of AR, businesses can transform their maintenance practices and unlock new opportunities for growth and success.